Metso Pioneers Low-Carbon Steel Production with Hydrogen Pilot Plant

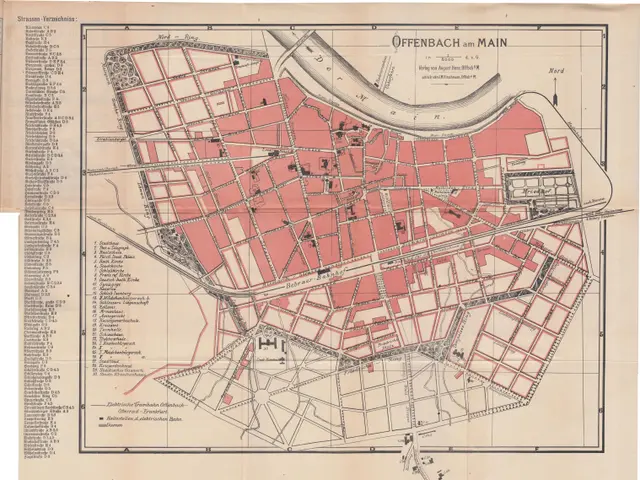

Metso, a global leader in process industries, is actively exploring low-carbon steel production. It's currently developing concrete projects for steel and ilmenite processing, though specific partners or customers remain undisclosed. Notably, Metso operates a hydrogen-based iron ore pre-reduction plant in Frankfurt, demonstrating its commitment to innovation in steel processing technology.

Metso's Frankfurt plant, part of its Circored pilot project, uses hydrogen as a reducing agent for continuous iron ore pre-reduction. The system integrates preheating, reduction, gas cleaning, and recycling systems for hydrogen and dust. This allows for the testing of various iron ore qualities and validation of process parameters. The resulting data will be crucial for designing future commercial-scale plants.

Metso aims to define operating windows for different ore qualities, supporting customers in transitioning to low-carbon steel production. The direct reduction process can be combined with DRI melters or other melting technologies. Moreover, electric heaters enable nearly CO2-neutral operation of the plant.

Metso's Frankfurt pilot plant marks a significant step towards low-carbon steel production. By validating process parameters and defining operating windows for different ore qualities, Metso is paving the way for future commercial-scale plants. The company's commitment to developing concrete projects for steel and ilmenite processing, along with its innovative use of hydrogen, positions it at the forefront of sustainable steel production.

Read also:

- Mecklenburg-Vorpommern's Controversial Spending: Calendars, Fish Ladders, and Parking Garages

- Berlin's Friedrichstraße and Checkpoint Charlie Redesigns Delayed by Budget Cuts

- Koblenz Explores Sewage Sludge Incineration Amidst 'Black Book' Revelations of Costly Investments

- Covid-19 Strains German Hospitals: Severe Nurse Shortage Threatens Care